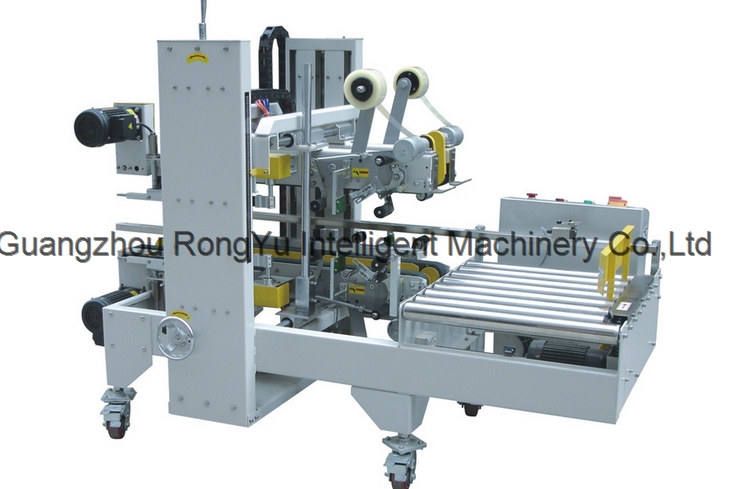

Carton box folding machine at the best price

Automatic aging machine for A60Led bulb

MOQ :1 set

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Credit Card,Western Union,Money Gram,Money Order,Pay Pal,Other

Product details

Supply Ability

- Supply Ability:50 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:1100 cmWidth:200 cm

- Height:160 cm

Product Specifications

- Brand name:RONGYU

Product Description

Automatic aging machine for A60 Led bulb

Application:

Automatic aging machine for A60 Led bulb is a new type of aging machine.This model can help the factory cut down the cost of producing led bulb.And the new aging machine has excellent advantages.The complete led bulb go through the machine with letter S way.

Process requirement

Automatic aging machine for A60 Led bulb .

Available for : AC220/110V(5-16.5W,power factor:0.6-0.98),The whole power count as single light 95V/12W

Aging line working process :

Automatic aging machine for A60 Led bulb is a new type of aging machine.

working with automatic assembly line --normal temperature low pressure(5mins)--normal temperature normal pressure(5mins)--normal temperature normal pressure (5mins)--normal temperature normal pressure (5mins)--normal temperature normal pressure impact open (5mins, electronic on and off every 5 seconds)--normal temperature normal pressure(5mins)--automatically unload the light (with power test and qualified product test),finish the whole process . Totally 6 working stations. The power for test area is the stander one, the other area will be options(pick 1 from 6 can be set for every working area).

Equipment requirement

Automatic aging machine for A60 Led bulb is a new type of aging machine.

1.The capacity 1200pcs/H, the aging time will design as 30mins(fit for the LED light bulb Diameter under 60MM)

Working steps :

Automatic aging machine for A60 Led bulb .

The working speed can be adjusted.

A: The operating speed could match with the assembly production line.

B: Move forward : For automatically load the product,will had accurate go step and stop step.

C: For the test and product unload ,operating for the steps go and stop convey the signal to PLC.

The control program:

1. Showed the voltage data of each area.Two bottoms for emergency stop operating ,power supply for the aging line will be three-phase four- wire

2. The power supply count as single light bulb 95V/12W, the power of Voltage regulator and isolation transformer for each area is 5KW,isolation transformer has 2 kinds of voltage 120V and 230V.The Voltage for 6 working area can be change from 0-250V.Available for narrow voltage product and width voltage product. The aging model for each area can be change.

Control program:

1. Adopt the PLC control program

2. All electric appliance control by the control cabinet. The 6 working area was made by combination steel window glass. Each window can be take off. Totally closed , has the protection system in the bottom

Installation Requirement:

1. Installation voltage: three-phase four- wire 380V 50Hz 12kw

2. Security protect system, control program has the caution system and the emergency stop system , for protect the worker from injury or accident .

3. The equipment meet the needs of SJ/T10533-1994

(The requirement of anti-static technology to electronic equipment manufacturing ),the belt and tool meet the needs.

4. The material for the machine should confirm to the environmentally protection.

5. The machine should have the protection system for the lube ,for protect the environment.

6. The machine noise should meet the stander environment requirement.

contact details:

Email: ivy@rongyujixie.com

Phone / what's app/wechat: +86-18820014694

www.rongyujixie.com

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer

Company Location: GUANG DONG

Year Established: 13YRS

You May Like

-

Carton box folding machine at the best price

-

T8 light tube packing machine

-

Aladdin prize - smart box

-

automatic carton machine

-

Automatic Shrinking and wrapping machine

-

Automatic folding cap sealing machine

-

LED E14 lamp bulb assembly machine

-

Automatic folding mchine for led bulb--Hook device

-

Automatic cartoning box machine line

-

LED bulb assembly line machine