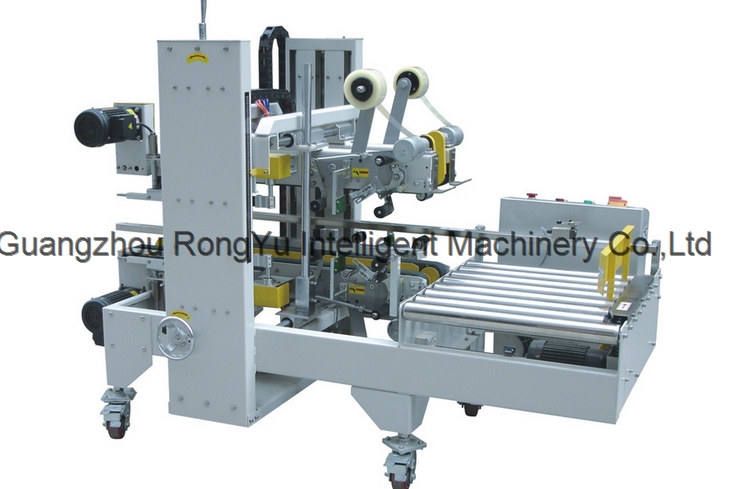

Carton box folding machine at the best price

LED bulb assembly line machine

MOQ :1 set

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Credit Card,Western Union,Money Gram,Money Order,Pay Pal,Other

Product details

Supply Ability

- Supply Ability:50 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:320 cmWidth:120 cm

- Height:165 cmLogistics Weight:1200.000 kg/set

- Packaging:1 set

Product Specifications

- Brand name:Rong Yu machinery

Product Description

Process introduction:

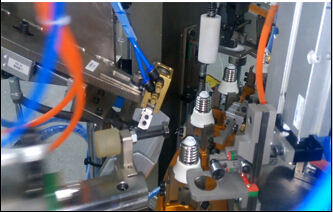

1. Ball bubble lamp assembly machine production process: power supply warehouse, physical and hold lamp holder, mount the rivet, the light test, pull cover and seal bubble gum, sealing foam, cutting

2 applicable specifications: G45\A55\A60, etc.

3 production efficiency: the actual output 1400PCS/ hours or more

An overview of the process flow of automatic assembly line

1, led ball bubble lamp automatic assembly production line applicable to the A19 ball bubble lamp automatic loading and a lamp cap, a shear line, rivet, power detection and pressure pin (pin 12), automatic glue injection, an automatic cover pressure blister etc. work. Equipment design is simple, can replace most of the manual operation of the process.

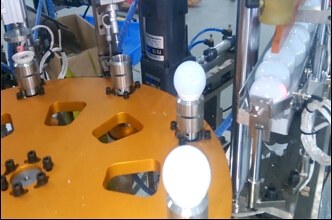

2, the specifications for blister diameter 45-75mm, high H=80-130mm lamp products; E26, E27 free welding cap. (E14 lamp B22 lamp replacement tool, customized)

3, process flow:

1) large disc assembly structure: automatic lamp holder, lamp holder, automatic loading and automatic trimming, power detection, pressure rivet, pin;

2) the small disc assembly structure: the artificial upper blister, the note glue, the cover pressure shell;

3) the total number of workers 3 people, 1400 per hour.

4, on the material

1) lamp, rivet, bubble shell is easy to scratch, using artificial material on the rotating disk by the mechanical hand on the host table material;

2) lamp with free welding cap.

5, equipment requirements:

1) equipment working environment (preferably with independent working space), and adhere to the daily cleaning, fuel lubrication.

2) equipment supply air clean, avoid water, oil and other debris into the pneumatic system, the pressure to reach 0.6MPa above; supply three-phase five wire power supply, power 2KW.

3) because most of the work by the mechanical implementation of reason and maintenance can not be separated, the buyer should according to the actual situation of the regular of the equipment for maintenance.

4) the device, which belongs to the precision machinery production, the consistency of raw materials will directly influence on the processing result, raw materials lead to inconsistent defective products are not included in the scope of acceptance, the visual detection of one-time acceptance qualified rate is more than or equal to 90% (one-time pass rate and raw material consistency).

Guangzhou Rong Yu Intelligent Machinery Co., Ltd.

Tel: 020-81234998 Cell:+8618820014694

Official website: www.rongyumachine.com/

www.rongyujixie.com

Gu

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer

Company Location: GUANG DONG

Year Established: 13YRS

You May Like

-

Carton box folding machine at the best price

-

T8 light tube packing machine

-

Aladdin prize - smart box

-

automatic carton machine

-

Automatic Shrinking and wrapping machine

-

Automatic folding cap sealing machine

-

LED E14 lamp bulb assembly machine

-

Automatic folding mchine for led bulb--Hook device

-

Automatic cartoning box machine line

-

LED bulb assembly line machine